Reverse engineering

including 3D scanning and data preparation

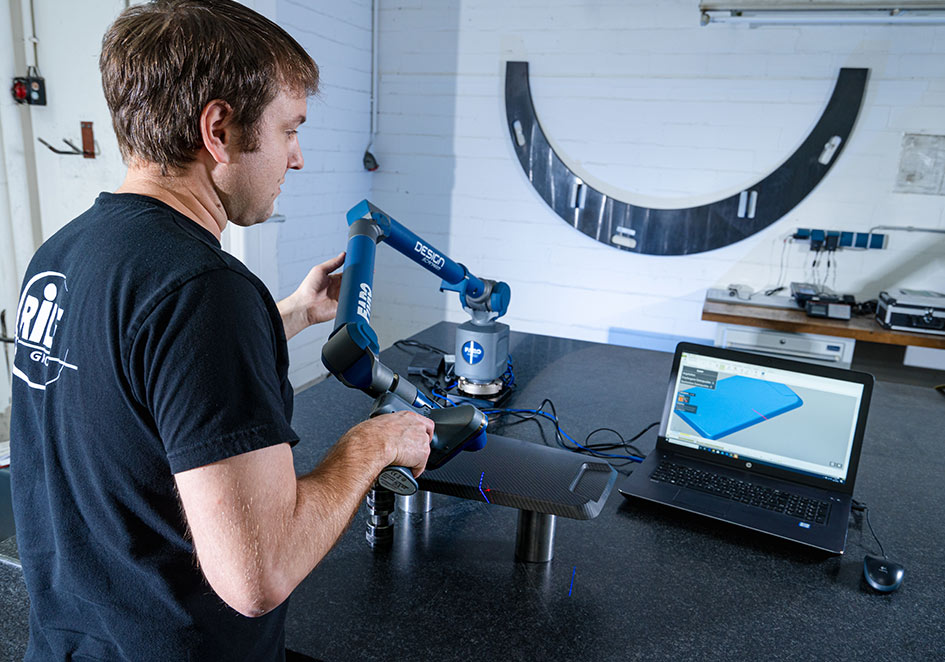

Components without technical drawings or CAD data can be reconstructed or digitised by reverse engineering. For this purpose, we use the latest hardware and software solutions in the field of 3D scanning and data preparation. During scanning, a 3D framework is created, comparable to a 3D photo. Subsequently, the 3D raw data is clearly evaluated and parametrically prepared by using Geomagic software. In addition, a fully defined CAD model is generated or constructed.

This process saves time and costs, as the raw data already represents a complete CAD model or only a few adjustments are necessary.

Frequent areas of application: spare parts business, medical/dental, model making, ...

Design & construction

Based on the CAD model provided via reverse engineering or by the customer, a new or a redesign of your component is carried out, if desired. Particularly in the field of additive manufacturing, component optimisation makes sense in order to be able to produce cost-effectively. At the same time, the molds, devices and test gauges are designed.

On the basis of your idea, a first prototype can be produced that can later go into series production.

We use common software moulds for this.

Composite

Carbon ist einer der faszinierendsten Werkstoffe der Zukunft. Er vereint hohe Festigkeiten mit geringem Gewicht. Einzigartige Voraussetzung für den energieeffizienten Leichtbau der Zukunft, der quer durch alle Industriebereiche zunehmend an Bedeutung gewinnt. Selbstverständlich verarbeiten wir auch alle gängigen Faserverbund-Werkstoffe.

Durch unser führendes Know-How in der Entwicklung, Planung und Produktion können wir ein einzigartiges Produktportfolio und erstklassigen Kundenservice anbieten.

Quality assurance

After finishing, the finished component has to be measured in one of the three air-conditioned precision measuring rooms, either tactilely or by scanning respectively laser. The target/actual comparison (deviations) of the scanned component to the existing CAD/volume model is clearly visualised and evaluated by means of false color display on the 3D model. If the component is measured tactilely, a measurement report is created. Both evaluations are of course made available to our customers on request.

In addition, high-precision measuring devices are used for the non-destructive testing of the test bars, which are produced each time, especially in the metal printing process.

The strength of the manufactured component is validated by tensile samples and their tensile tests.

Machines

Extract from our machinery

5-axis milling machines

![[Translate to Englisch:] 5-Achs Fräsmaschinen](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/1_maschinen_5achs_fraesmaschinen1.jpg)

![[Translate to Englisch:] 5-Achs Fräsmaschinen](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/1_maschinen_5achs_fraesmaschinen2.jpg)

![[Translate to Englisch:] 5-Achs Fräsmaschinen](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/1_maschinen_5achs_fraesmaschinen3.jpg)

5-axis milling machine DMG HSC 105 Linear with 3D control Siemens 840D SL Operate

working range: X 1050 mm / Y 800 mm / Z 560 mm, clamping surface Ø 950 mm, swivel range B-axis +10/-110°, C-axis 360°, loading weight max. 800 kg, tool holder HSK-A 63, tool magazine with 60 places, drive power 43.5 kW, speed range from 1-28000 rpm, infrared measuring probe

5-axis milling machine CMS NC-Ares 48-18 APC PX5 with pendulum tables for carbon and ureol processing

working range: X-axis 4800 mm, Y-axis: 1800 mm, Z-axis: 1200 mm, combi vacuum tables with grid milling and T-slots: 12H11, incl. 10 vacuum connections per table controlled via CNC, clamping area per table: 2160 x 1360 mm, max. workpiece weight: 1000 kg/m²

5-axis milling machine Bimatec Soraluce F-MT 4000 with CNC control Siemens 840D SL

working range: X 4000 / Y 1300 / Z 1600, universal swivel head, spindle speed 5000 1/min., torque 900 Nm, clamping surface 4000x1240, clamping weight 8000 kg, integrated rotary table, faceplate diameter 1600 mm – max. turning diameter 2000 mm, max. speed 400 1/min, max. workpiece weight for turning 3000 kg – balance sensor system, tool magazine 192 places, rapid traverse speed 45 m/min., infrared measuring probe

model making

![[Translate to Englisch:] Modellbau](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/2_maschinen_modellbau1.jpg)

Format band saw FBS 740-2 F15

max. length/width: 1500 mm x 710 mm

ecoAvanti glueing table with hurricane exhaust system

Eco welding table 3000 x 1500 x 200 mm

CNC Cutter

![[Translate to Englisch:] CNC Cutter](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/2_maschinen_cnc_cutter.jpg)

Aristomat TL 1617 PLC for cutting PrePreg

Working area 1520 x 1700 mm

Clean room and laminating workstation

![[Translate to Englisch:] Reinraum und Laminierarbeitsplatz](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/4_maschinen_reinraum1.jpg)

Winter Vacuum Membrane Press ÖKOVAC

working area 1150 x 2850 mm

max. workpiece height 400 mm

heating power 2x2,5 kW

Autoclave technology

![[Translate to Englisch:] Autoklaventechnolgoie](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/5_maschinen_autoklaventechnologie1.jpg)

Maroso Autoclave Ø 1500 mm and 3000 mm

max. 250° C, max. 6 bar

max. load 450 kg

Maroso Autoclave Ø 2500 mm and 5000 mm

max. 250° C, max. 12 bar

max. load carbon: 200 kg

max. load aluminum: 600 kg

Heating cabinet

![[Translate to Englisch:] Wärmeschrank](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/6_maschinen_waermeschrank1.jpg)

![[Translate to Englisch:] Wärmeschrank](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/6_maschinen_waermeschrank2.jpg)

Binder Drying Oven model 9010-0267 FP720-400 V

length/width/height: 1090 x 1390 x 1760 mm

Weight: 237 kg

Nabertherm Air Circulation Chamber Oven N250/85HA with controller P470

Usable space: 480 x 600 x 480 mm (WxDxH)

Charging height: 900 mm

Permissible charge weight: Total 250 kg

component trimming and finishing

![[Translate to Englisch:] Bauteilbeschnitt und Nachbearbeitung](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/7_maschinen_nachbehandlung_1.jpg)

![[Translate to Englisch:] Bauteilbeschnitt und Nachbearbeitung](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/7_maschinen_nachbehandlung_2.jpg)

![[Translate to Englisch:] Bauteilbeschnitt und Nachbearbeitung](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/7_maschinen_nachbehandlung_3.jpg)

![[Translate to Englisch:] Bauteilbeschnitt und Nachbearbeitung](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/7_maschinen_nachbehandlung_4.jpg)

3 pieces sandblasting cabins,

e.g. MHG SMG 50 K-P ATEX

working area: 550/800 x 1100 x 660 mm (HxWxD)

extraction tables CV and AF

4 workplaces with central exhaust and dust extraction system from Hurrican

CNC panel milling machine Winter Routermax-Basic 1325 with Hurrican extraction system

working range: X-axis 1300 mm / Y-axis 2500 mm / Z-axis 300mm

Meba horizontal metal band saw MEBAeco 510 3D

Cutting range: 90° 510 700 x 500

3D Printer

![[Translate to Englisch:] 3D Drucker](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/8_maschinen_3d_drucker_1.jpg)

![[Translate to Englisch:] 3D Drucker](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/8_maschinen_3d_drucker_2.jpg)

Stratasys Fortus Forte 450 MC for plastic parts

Print area: 406 x 355 x 406 mm

Material feed: capacity for two model material and two support material containers each, automatic container change

Wash-out function

Layer thicknesses:

- 0.125 / 0.178 / 0.254 / 0.330 mm

- ABS-M30, ABS-M30i, ASA, FDM Nylon 12, PC (all types), ULTEM (all types), ST-130: 0.254 mm

- ABS (all types), ASA, FDM Nylon 12, PC (all types), ULTEM (all types): 0.178 mm

- ABS-ESD7, ABS-M30i, ASA, FDM Nylon 12, PC (all types): 0.127 mm

- ABS-M30, ABS-M30i, ASA, PC (all grades)

- high performance plastics ULTEM 9085 and 1010

SLM 280 2.0 for metal parts (Selective Laser Melting – SLM)

- max. part size: 280 x 280 x 365 mm³

- variable layer thickness 20µ - 90µ

- density of additively manufactured metal parts is over 99.5 percent

- very high precision and fine details possible

- for the production of high quality metal parts made of e.g. stainless/tool steels, aluminum alloys or titanium

Press

Quality assurance measurement

![[Translate to Englisch:] QS - Messtechnik](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/9_maschinen_messtechnik_1.jpg)

![[Translate to Englisch:] QS - Messtechnik](/fileadmin/user_upload/lightweight/5_prozesse_maschinen/maschinen/9_maschinen_messtechnik_2.jpg)

FARO scanning arm

Measuring range 2500

Galdabini-Quasar 50 kN universal testing machine

Metal tensile tests according to ISO 6892

Force measurement >1/100 of nominal load (grade 0.5)

(Optional >1/500 with grade 1)

Coordinate measuring machine Zeiss Contura

Measuring range: 1000 / 1600 / 600 mm

Coordinate measuring machine Zeiss MMZ G 40-50-25

Measuring range: 4000 / 5000 / 2500 mm

![[Translate to Englisch:] Fertigung](/fileadmin/user_upload/lightweight/1_startseite/rile_lightweight_design_fertigung.jpg)

![[Translate to Englisch:] Prozesse und Maschinen](/fileadmin/user_upload/lightweight/1_startseite/rile_lightweight_design_branchen.jpg)